Plastic Optical Fiber Cable: The Versatile, Cost-Effective Solution for Next-Gen Connectivity

For short-reach connectivity needs, Plastic Optical Fiber cable proves that fiber optics doesn’t have to be expensive or complicated.

2025-09

While glass fiber cables dominate long-haul and high-performance networks, Plastic Optical Fiber cable has emerged as a star in short-reach, high-volume applications—offering a unique blend of affordability, flexibility, and ease of use that glass simply can’t match. From consumer electronics to industrial automation, POF is redefining connectivity by making fiber optics accessible to industries and users that once found traditional glass fiber too costly or cumbersome.

Why Plastic Optical Fiber Cable Stands Out

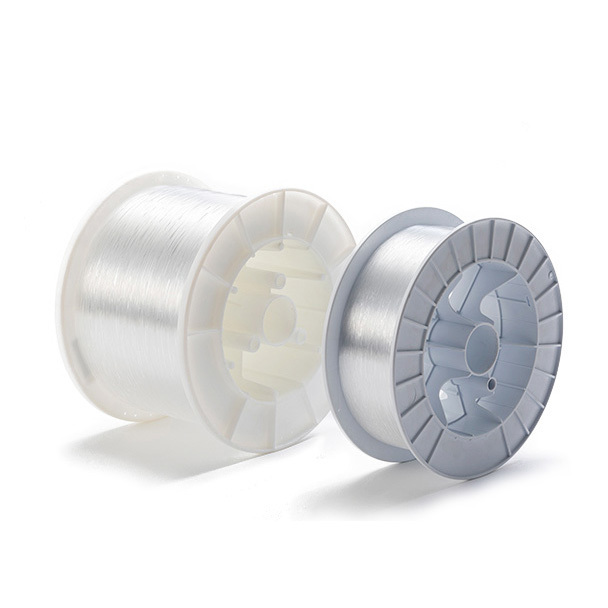

At its core, POF uses a plastic (typically polymethyl methacrylate, PMMA) core and cladding, instead of glass. This fundamental difference gives it a host of advantages that make it ideal for short-distance (up to 100 meters) applications:

1. Unbeatable Affordability

POF’s plastic construction is significantly cheaper to manufacture than glass fiber, especially for high-volume orders. Unlike glass, which requires precision drawing and handling, plastic can be extruded quickly and in large quantities—lowering production costs by up to 50% compared to standard glass fiber cables. For consumer electronics brands (e.g., TV manufacturers, audio equipment makers) or small-to-medium enterprises (SMEs) with tight budgets, this means accessing the benefits of fiber optics (immunity to electromagnetic interference, high bandwidth) without the premium price tag.

2. Exceptional Flexibility & Durability

Glass fiber is brittle and prone to breakage if bent or mishandled—a major downside in environments where cables are frequently moved or installed in tight spaces. POF, by contrast, is highly flexible (with a bend radius as small as 20mm) and resistant to impact and vibration. This makes it perfect for:

- In-Home Entertainment: Connecting soundbars, gaming consoles, and 4K TVs without the risk of breaking cables during setup.

- Automotive Applications: Routing cables through the tight confines of a car’s interior (e.g., for infotainment systems, driver-assist sensors) without compromising performance.

- Industrial Automation: Withstanding the harsh conditions of factories (vibration, temperature fluctuations) where glass fiber would fail.

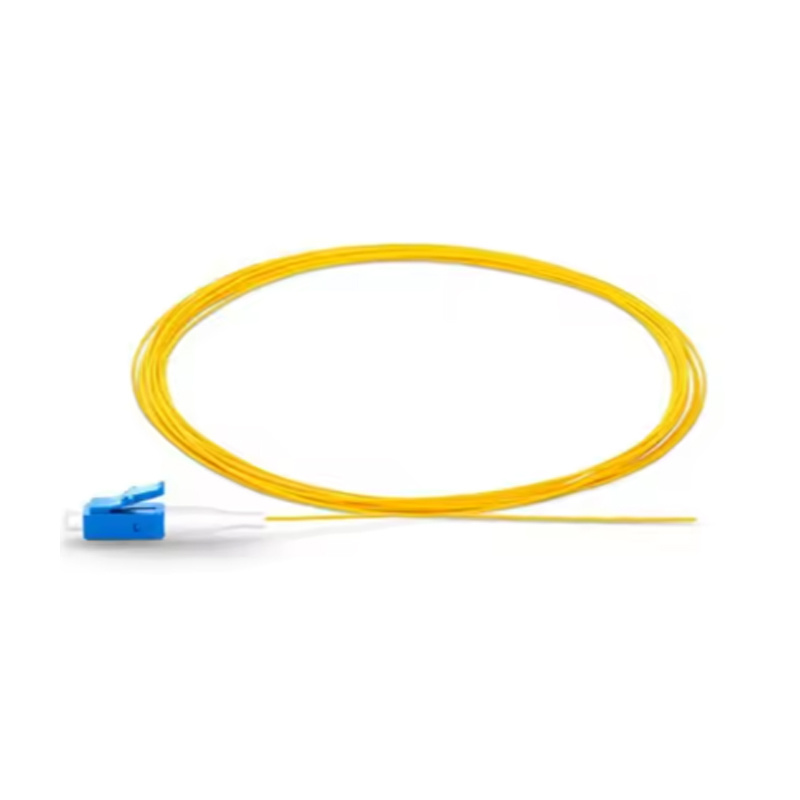

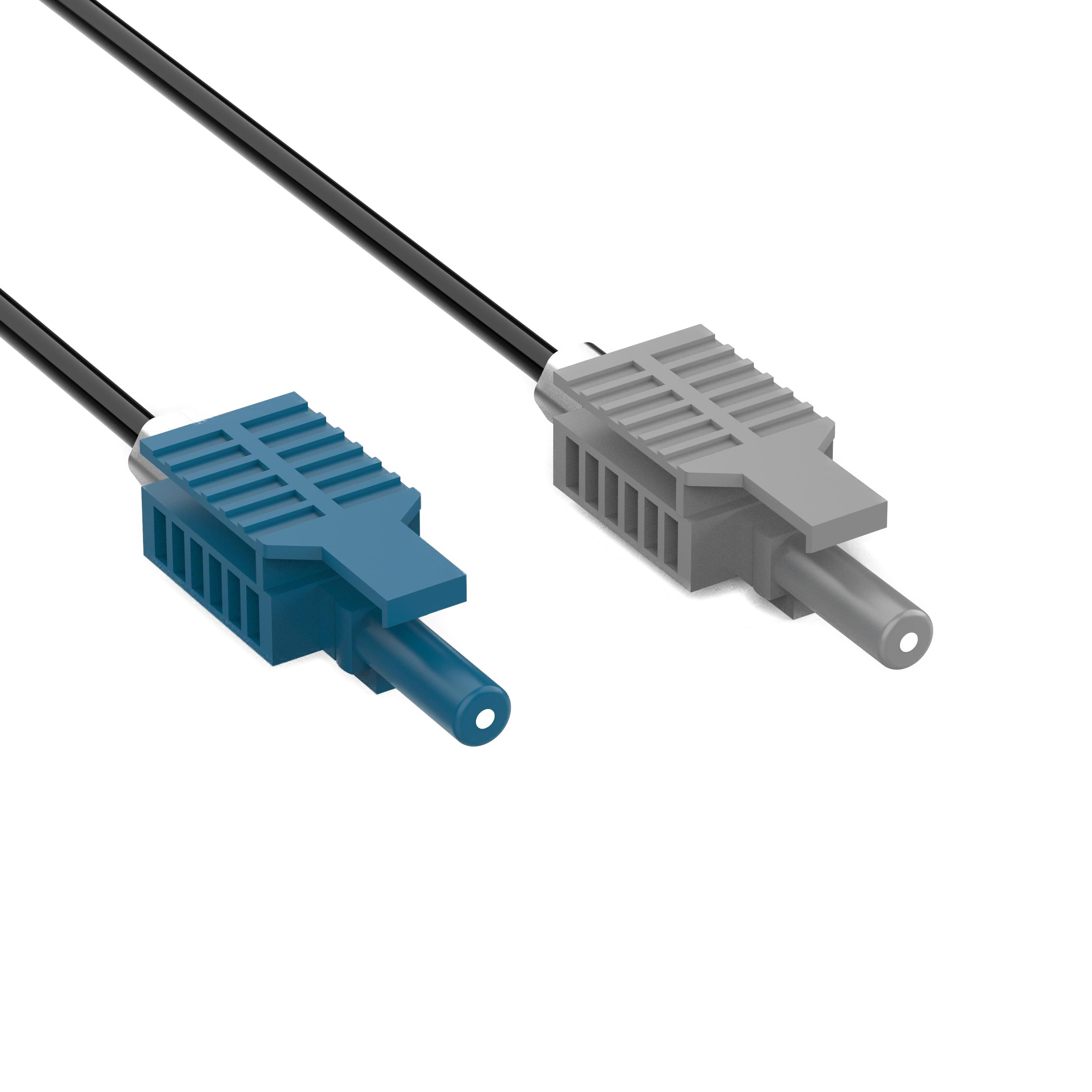

3. Easy Installation & Maintenance

Installing glass fiber requires specialized tools (fusion splicers, cleavers) and trained technicians—adding to the total cost of ownership. POF, however, can be cut with standard scissors, terminated with simple crimp-on connectors, and installed by anyone with basic DIY skills. This not only reduces installation time (by up to 70% compared to glass) but also lowers maintenance costs, as repairs can be done on-site without waiting for specialized teams.

4. Immunity to EMI & Secure Data Transmission

Like glass fiber, POF transmits data via light signals, making it completely immune to electromagnetic interference (EMI) and radio frequency interference (RFI). This is a game-changer for industrial settings, where heavy machinery, motors, and power lines can disrupt copper cables. Additionally, POF is difficult to tap (unlike copper, which emits electromagnetic signals that can be intercepted), making it a secure choice for transmitting sensitive data in retail (POS systems) or healthcare (patient monitoring devices).

Key Applications of Plastic Optical Fiber Cable

- Consumer Electronics: Audio/video cables (HDMI alternatives), smart home sensors, and gaming peripherals.

- Automotive: In-car infotainment, ADAS (Advanced Driver Assistance Systems), and lighting controls.

- Industrial Automation: Factory robots, sensors, and control systems (where EMI immunity is critical).

- Retail & Healthcare: POS terminals, inventory trackers, and medical equipment (secure, interference-free data transfer).

For short-reach connectivity needs, Plastic Optical Fiber cable proves that fiber optics doesn’t have to be expensive or complicated. It’s a practical, versatile solution that bridges the gap between copper’s affordability and glass’s performance—making it the smart choice for businesses and consumers alike.

Related News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.