Hollow-Core Fiber: A Key Breakthrough for Data Center Interconnect

Hollow-core fiber (HCF) uses air instead of glass to transmit light, delivering lower latency, lower loss, and higher capacity than conventional fibers. With rapid progress in technology, HCF is poised to enable next-generation data center interconnects and other low-latency, high-capacity networks.

2025-09

With the explosive growth of computing power demand, overseas data center construction has entered the era of GPU clusters numbering in the tens of thousands or even hundreds of thousands. The need for interconnection between data centers, connectivity across ultra-large computing clusters, and transmission within metropolitan networks is becoming increasingly urgent. Data Center Interconnect (DCI) is therefore reaching a critical stage of development. As an important technical solution for DCI, hollow-core fiber (HCF) offers significant technical advantages and strong market potential, with commercialization expected to accelerate in the coming years.

01 What is Hollow-Core Fiber?

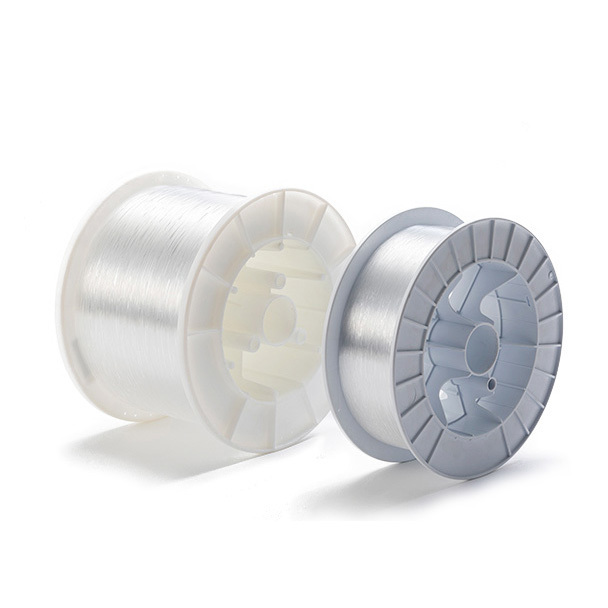

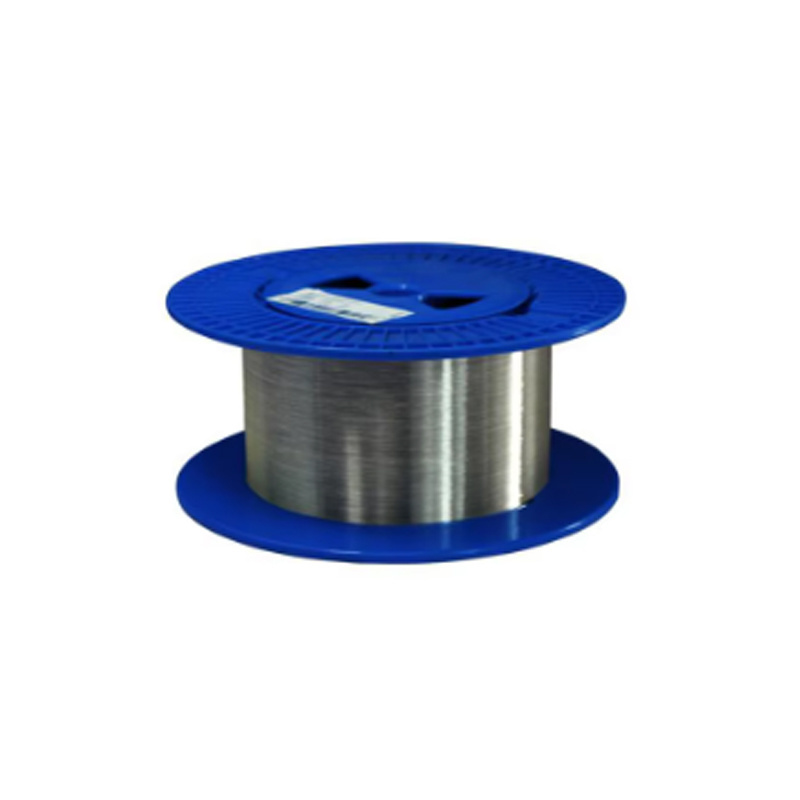

Hollow-core fiber (HCF) uses air as the transmission medium instead of the traditional glass core (silica, primarily SiO₂).

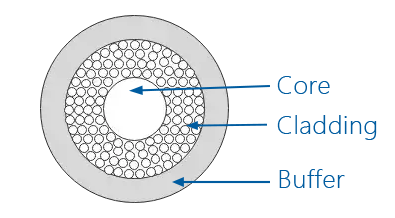

Like conventional fibers, HCF consists of three parts: core, cladding, and coating. The key difference lies in the design of the core and cladding:

Core: air-filled

Cladding: microstructured design, usually an arrangement of microscopic air holes running along the fiber length. These holes are periodically distributed, making the cladding cross-section resemble a honeycomb lattice formed by silica struts.

02 Principle vs. Conventional Optical Fiber

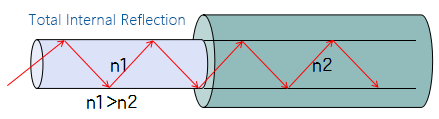

Conventional Fiber: Guides light through the principle of total internal reflection. The refractive index of the core (n₁) is higher than that of the cladding (n₂), confining light within the glass core as it reflects along the interface.

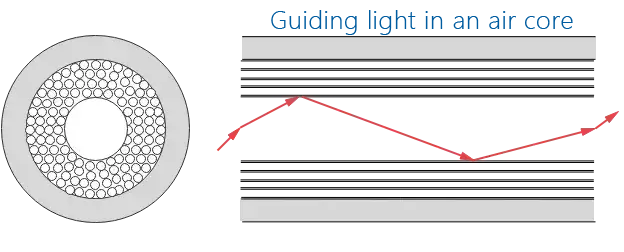

Hollow-Core Fiber: Since the air core has a lower refractive index than the cladding, total internal reflection cannot occur. Instead, special cladding designs such as photonic bandgap structures are used. The periodic air-hole structure causes strong scattering and coherent interference, forcing specific wavelengths and incident angles of light to remain confined within the hollow core.

Working Principle of Conventional Optical Fiber

Working Principle of Hollow-Core Fiber

03 Technology Development Timeline

~2000: Photonic Bandgap Hollow-Core Fibers (PBG-HCFs) were demonstrated, but with high attenuation (>1 dB/km).

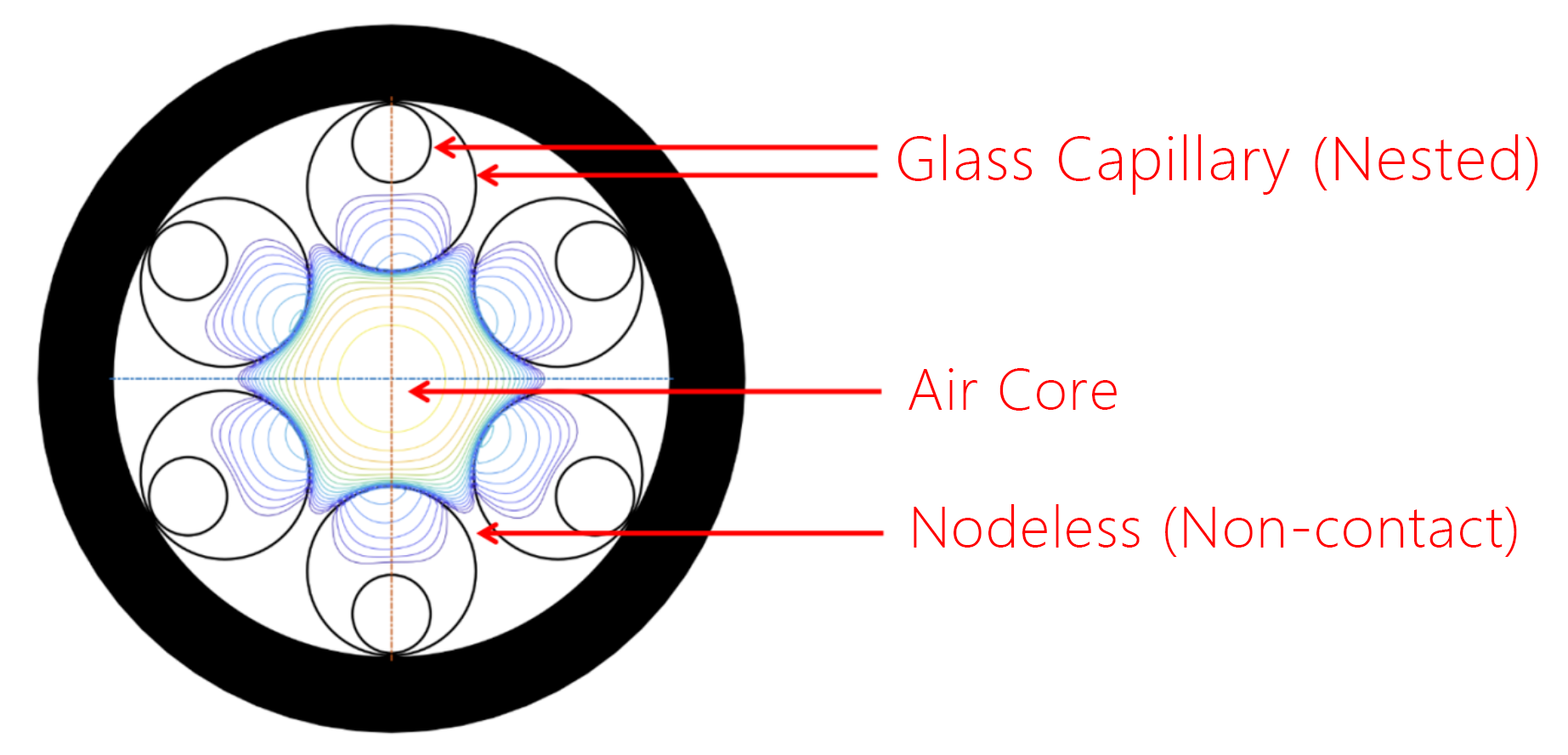

2010s: Anti-Resonant Negative Curvature Fibers (AR-HCF/NCF) were introduced, greatly improving bandwidth and reducing attenuation.

Recent years: Nested Anti-Resonant Fibers (NANFs) achieved an attenuation of 0.28 dB/km in laboratories, approaching the performance of standard silica fibers (G.652D).

The technology has advanced from a laboratory proof-of-concept to the stage of pre-commercial deployment.

04 Key Advantages of HCF

1.Low Latency

Light propagates in air close to the speed of light in vacuum.

- Solid-core fiber latency: ~5 μs/km

- Hollow-core fiber latency: ~3.46 μs/km

- A 1,000 km link reduces latency by ~1.54 ms.

2.Low Attenuation

The theoretical minimum attenuation of HCF is below 0.1 dB/km, surpassing conventional silica fiber (~0.14 dB/km).

3.High Capacity

Light–matter interaction in air is extremely weak, reducing nonlinear effects by 3–4 orders of magnitude compared to conventional fibers. This allows higher input power and greater capacity and distance.

4.Other Advantages

- Broader wavelength support

- Low and engineerable dispersion

- Low thermal sensitivity

- High radiation resistance

05 Comparison with Conventional Fiber

| Parameter | Conventional Silica Fiber | Hollow-Core Fiber (HCF) |

|---|---|---|

| Transmission Medium | Silica glass | Air (hollow core) |

| Refractive Index | ~1.44 | ~1.0003 |

| Latency | ~5 μs/km | ~3.46 μs/km (~30% lower) |

| Attenuation | ~0.14 dB/km | <0.1 dB/km (theoretical) |

| Nonlinear Effects | Significant | Extremely low (3–4 orders less) |

| Dispersion | Inherent, requires DCM | Low, engineerable |

| Maturity | High, commercialized | Emerging, pre-commercial |

06 Current Challenges

Manufacturing Complexity: Extreme precision required in symmetry, hole size, and wall thickness; maintaining uniformity over long lengths remains difficult.

Splicing Issues: Fusion splicing with standard SMF results in high loss; special transitions are needed.

Bending Sensitivity: Loss remains sensitive under small bending radii, despite improvements in NANF.

Cost: Currently much higher than silica fiber; large-scale deployment depends on yield and supply chain maturity.

07 Commercialization and Market Landscape

International Progress: BT’s subsidiary Lumenisity has launched HCF products and conducted DCI pilot deployments. NTT, CORNING, and other players are active in R&D.

Domestic Efforts: Huawei, Chinese Academy of Sciences, and other institutes are pursuing research, focusing on supercomputing interconnects and metro networks.

Priority Application Scenarios:

- Low-latency links for financial trading

- Data center interconnect (DCI)

- Supercomputing cluster interconnects

- Aerospace, defense, and secure communications

08 Future Development Trends

Performance approaching or surpassing silica fiber: Targeting ultra-low attenuation below 0.1 dB/km.

Improved bend radius and reliability: Essential for data center cabling and submarine cables.

Standardization and ecosystem: Inclusion into ITU/IEEE standards anticipated.

Cross-disciplinary applications: Quantum communications, ultrashort pulse transmission, and mid-IR photonics.

Cost Reduction: With yield improvements and process maturity, large-scale commercialization is expected within 3–5 years.

Conclusion

Hollow-core fiber, with its unique advantages of low latency, low attenuation, low nonlinearity, and high capacity, is emerging as a strategic technology for data center interconnect and computing networks. As manufacturing techniques advance and the ecosystem matures, HCF is expected to be deployed first in DCI, financial trading, and supercomputing clusters, becoming a cornerstone of next-generation optical communication.

Related News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.