Optical Fiber for Encoder Signal Transmission in Servo Systems|A Key Technology for Robotics & Industrial Automation

Optical fiber improves servo motor encoder feedback with EMI immunity and reliable signal transmission. Ideal for robotics, CNC machines, and industrial automation.

2025-11

In modern robotics, CNC machines, and intelligent manufacturing, the communication link between the servo motor and servo drive plays a critical role in achieving precise motion control. The encoder inside the servo motor continuously sends real-time data—such as position, speed, and direction—to the servo drive to ensure accurate and stable operation.

However, as industrial environments become more complex and electrically noisy, traditional copper cables increasingly suffer from electromagnetic interference (EMI), signal distortion, and communication errors.

This is why optical fiber has become the preferred transmission medium for encoder feedback in servo systems.

This article explains why optical fiber is essential for servo encoder communication, the advantages of POF & HFBR fiber jumpers, and the key applications in robotics and industrial automation.

1. Why Servo Encoders Need Optical Fiber Transmission

Servo motors typically operate in harsh electrical environments that include:

- High-frequency switching signals

- Inverter noise and motor-generated EMI

- Large currents and fast PWM control

- Ground potential differences

- Long-distance wiring inside machinery or robot arms

These conditions often cause copper cables to suffer from:

- Encoder feedback errors

- Motor vibration or jitter

- Servo alarm faults

- Lost pulses or positioning instability

- Downtime and maintenance issues

By contrast, optical fiber is immune to EMI/RFI, providing stable, error-free signal transmission even in the most challenging conditions.

2. Key Advantages of POF Optical Fiber for Servo Encoders

The most widely adopted solution in servo communication is 1.0 mm Plastic Optical Fiber (POF) combined with HFBR transceivers and HFBR fiber jumpers.

1. Complete Electromagnetic Immunity

Optical fiber transmits signals using light, not electricity, making it resistant to noise from:

inverters, servo drives, high-power motors, IGBT modules, and switching power supplies.

2. Full Electrical Isolation for Improved Safety

Optical isolation prevents:

- Ground loops

- Surge damage

- High-voltage coupling

- Short-circuit propagation

3. Small Bend Radius for Robot Arm Wiring

POF features excellent flexibility with a minimum bend radius below 10 mm, making it ideal for:

- Multi-axis robot joints

- Dynamic drag chains

- High-frequency repetitive motion environments

4. Easy Installation and Maintenance

POF cables are lightweight and easy to cut, polish, and install on-site.

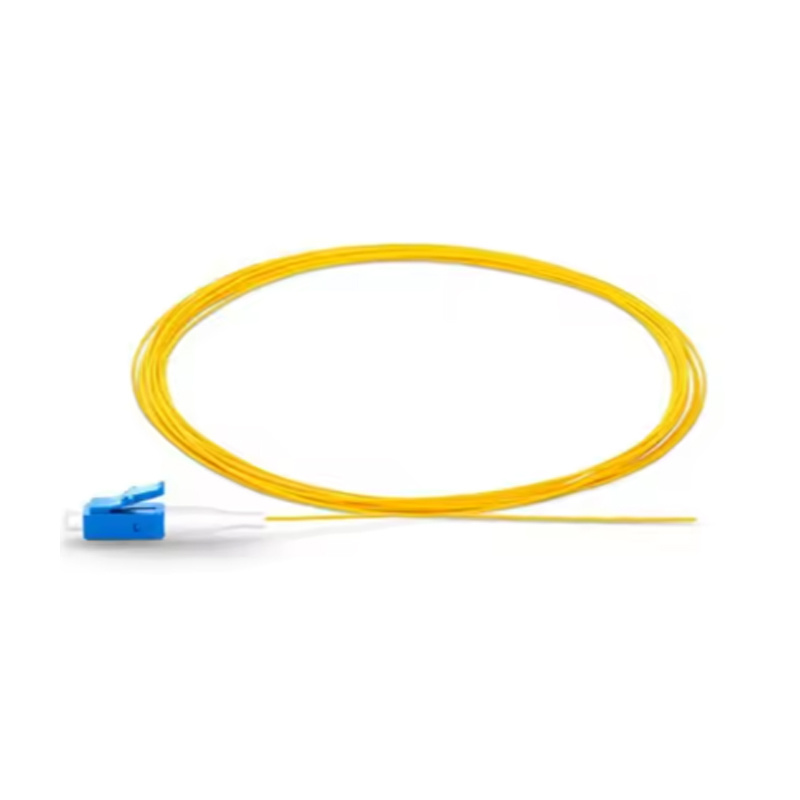

HFBR connectors (4501/4511/4531/4533 series) offer plug-and-play convenience.

5. Suitable Transmission Distance

POF supports typical encoder communication distances of:

- 10–50 meters for servo systems

- Up to 100 meters for industrial automation networks

This fully covers the needs of robots, CNC machines, packaging machinery, AGVs, and more.

3. System Structure of Optical Encoder Communication

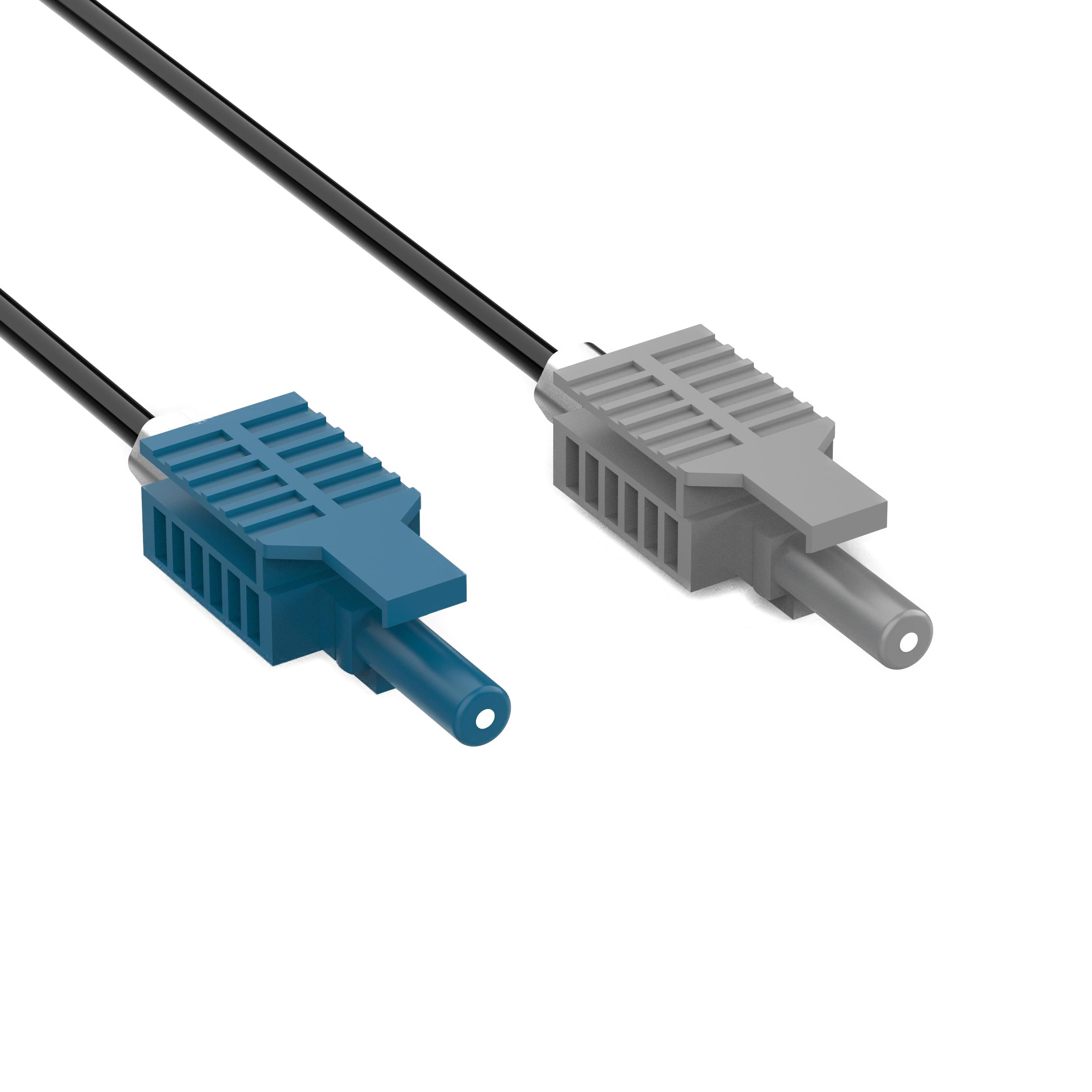

A complete optical servo encoder system includes:

1. Optical Encoder Interface on the Motor

Compatible with Mitsubishi, Panasonic, Delta, Yaskawa, etc.

2. HFBR Optical Transmitters & Receivers

Common models:

- HFBR-1521Z / 2521Z

- HFBR-1428Z / 2428Z

- HFBR-1528Z / 2528Z

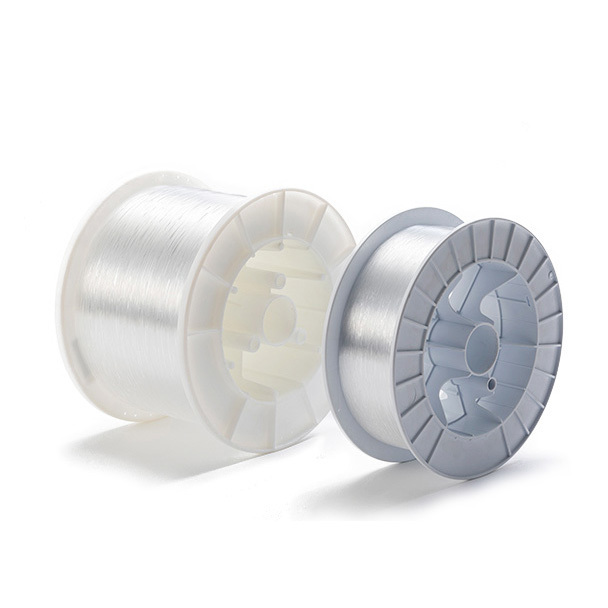

3. Plastic Optical Fiber Cable (POF)

Available options:

- 1.0 mm SI-POF

- 2.2 mm PE / LSZH / PA12 jacket

- Single-core or duplex versions

- Kevlar-reinforced industrial POF

4. Optical Receiver Module on the Servo Drive

Together, they form a highly stable high-speed communication system.

4. Typical Applications in Industrial Automation

1. Industrial Robots

Optical fiber is used between:

- Servo motor encoders → servo drives

- Servo drives → robot controllers

- Joints (J1–J6) inside robotic arms

2. CNC Machines and Machining Centers

For high-speed spindle feedback and linear motor control.

3. SMT, Packaging, and Assembly Equipment

Where high-speed and low-noise signal transmission is mandatory.

4. AGV/AMR Mobile Robots

Used for drive control, navigation motor feedback, and safety communication.

5. Automated Production Lines

Ideal for long-distance wiring in noisy industrial environments.

5. Ruiara Optical Fiber Solutions for Servo Encoder Transmission

Shenzhen Ruiara Co., Ltd. provides complete industrial optical fiber solutions, including:

● HFBR Plastic Optical Fiber Jumpers (4501/4511/4531/4533 Series)

Fully compatible with leading servo systems such as Mitsubishi, Panasonic, Delta, and Yaskawa.

● 1.0 mm Industrial Plastic Optical Fiber (POF Cables)

Available in PE, LSZH, PA12 jackets, with single-core, duplex, or Kevlar-reinforced structures.

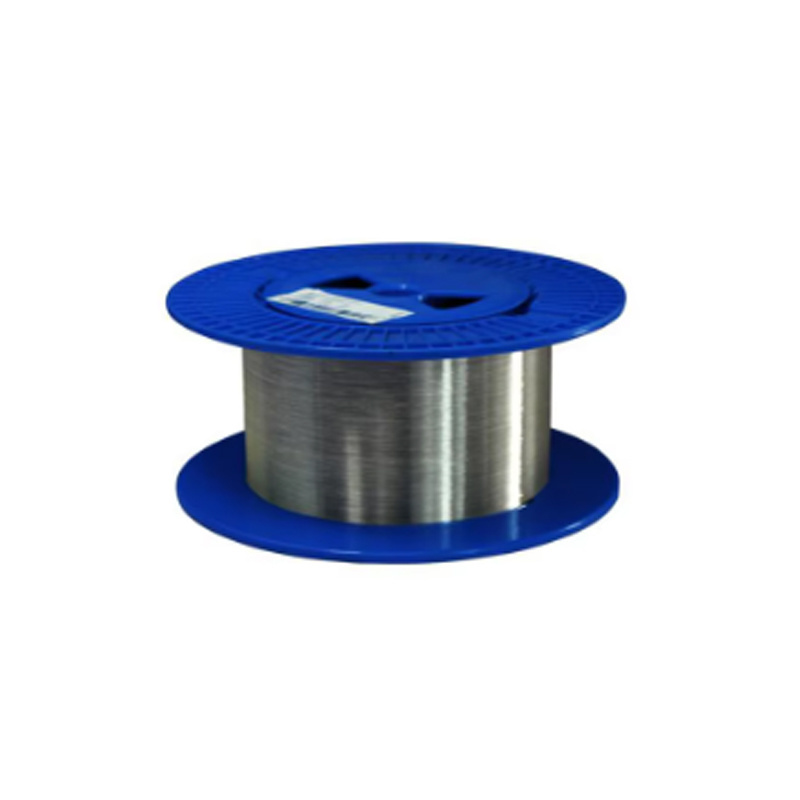

● Industrial-Grade Quartz Fiber Jumpers

Suitable for high-temperature or high-precision environments.

● OEM/ODM Customized Fiber Assemblies

Length, jacket material, connector type, color, polishing, and structure can all be customized.

Conclusion: Optical Fiber Is Becoming the Standard for Servo Encoder Communication

The reliability of servo encoder feedback directly influences the performance, accuracy, and lifespan of robotic and automated equipment.

With outstanding EMI immunity, electrical isolation, flexibility, and long-distance capability, optical fiber—especially POF and HFBR fiber jumpers—has become the preferred solution in modern industrial automation.

As robots and smart factories continue to evolve, optical fiber will play an even greater role in achieving high-precision, high-speed, and highly reliable motion control.

Related News

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.